Anti-slip regulations are guidelines and standards set by regulatory bodies within the stair industry to ensure that walking surfaces, such as floors, stairs, and ramps, provide adequate traction to prevent slips and falls. These regulations are crucial for maintaining safety in public, commercial, and residential buildings. Some key aspects of anti-slip regulations include surface coefficient of friction, design specifications, and maintenance requirements.

The Importance of Anti-Slip Regulation in the Stair Industry

Anti-slip regulations play a critical role in enhancing stair safety and preventing accidents by ensuring that stairways are designed, constructed, and maintained with adequate slip resistance. Regulations contribute to safety in several key ways including assurance of safe design and construction, mandatory inclusion of various safety features, routine maintenance and inspections, and reduction of slip and fall incidents.

Regulations help ensure safe design and construction of staircases through requirements such as visible nosings and adequate tread and riser dimensions. High-contrast nosings make the edge of each step more visible, aiding in depth perception and reducing the risk of missteps, particularly in dimly lit environments. Regulations demand uniformity in tread depth and riser height, which helps users maintain a consistent gait while ascending or descending stairs, reducing the likelihood of missteps.

Anti-slip regulations also require certain mandatory safety features such as handrails, guardrails, and non-slip tread materials. Regulations require the installation of handrails on both sides of the stairway, providing users with a secure grip to prevent falls and offer stability, especially for those with mobility issues. Mandates for non-slip materials or coatings on stair treads ensure that even when surfaces are worn or wet, they still provide adequate slip resistance.

Routine maintenance and regular inspections are yet another way in which anti-slip laws enhance stair safety and prevent injury. Regulations often require regular inspections to identify and repair hazards such as loose treads, worn anti-slip surfaces, or debris, ensuring that stairs remain safe over time. Specific cleaning protocols must also be followed. Ensuring that stairs are kept clean and free of contaminants (like water, oil, or ice) maintains their slip-resistant properties and reduces accident risk.

Anti-slip regulations are essential for creating safe stair environments, reducing the risk of accidents, and ensuring compliance with safety standards. By enforcing the use of slip-resistant materials, proper design, regular maintenance, and safety features like handrails, these regulations play a pivotal role in protecting public health and safety and enhancing the overall usability of stairways.

What is Anti-Slip Regulation for Stairs?

Anti-slip regulations exist in the stair industry for several critical reasons, all aimed at enhancing safety, reducing accidents, and ensuring accessibility. These regulations ensure guilty parties are held accountable for improper building methods that pose a danger to the public.

Anti-slip laws require stairs be in compliance with both legal and safety standards. This includes adherence to national and local building codes. These regulations help ensure that new constructions and renovations meet safety standards. Another standard that must be upheld is liability and legal protection. Compliance with regulations helps property owners and businesses avoid legal issues and liability claims arising from slip-and-fall accidents. It demonstrates a commitment to safety and due diligence.

Do Stairs Need to Be Slip Resistant?

Anti-slip laws and regulations are essential for reducing the number of accidents per year, as well as for reducing the degree of seriousness of each incident. Not only do these regulations aim to protect the general public, but they also aim to increase occupational safety for workers. Companies must abide by the checks and balances of compliance with legal and safety standards. Furthermore, anti-slip regulation promotes accessibility, especially in the case of the Americans with Disabilities Act (ADA). Inclusive designs not only protect the rights of the public, but also enhance usability and comfort for all.

Understanding OSHA Guidelines for Anti-Slip Stairs

OSHA provides an extensive list of guidelines related to anti-slip stairs. A few of the key areas of interest include:

- Stairway Platforms

- Stairway Railings and Guards

- Stair Treads and Risers

Each area of regulation is measured by the following factors:

- Strength

- Surface Conditions

- Visibility and Lighting,

- Inspections and Maintenance

- Signage and Warnings

Implementing Anti-Slip Solutions for Stairs

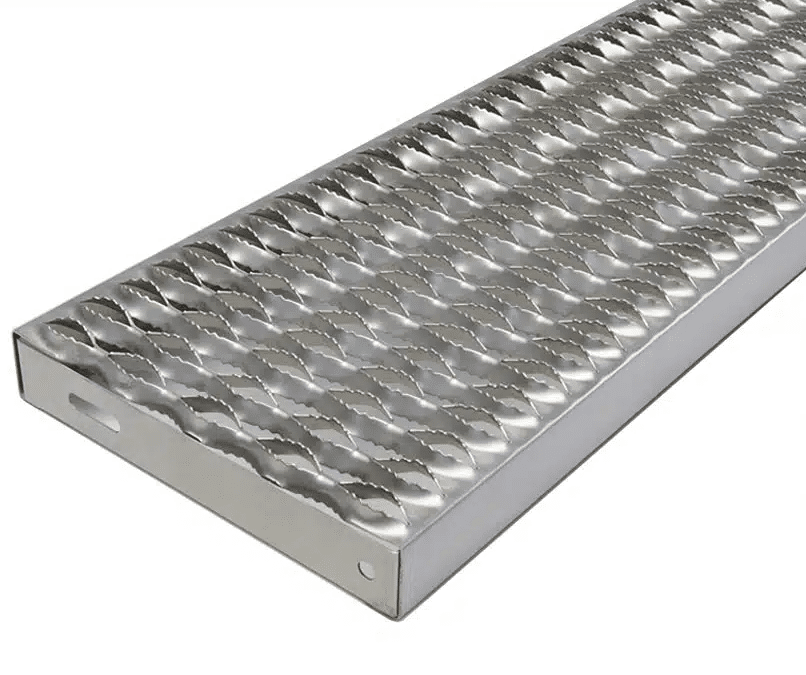

There are a plethora of options when it comes to implementing anti-slip solutions for your staircases. Some common and popular anti-slip materials include rubber treads, carpeted treads, fiberglass treads, and metal treads with abrasive surfaces. There are also non-slip paints and coatings available, including epoxy coatings and polyurethane coatings.

Beyond custom materials and coatings, there are also effective anti-slip treatments available, including etching solutions or anti-slip tape. Depending on what stage your project is in, there are also design considerations to take into account. This includes careful consideration of nosings, textured tread designs, integrated lighting, handrails, and other innovative solutions such as glow-in-the-dark treads or heated treads for countering ice.

Anti-slip solutions for stairs encompass a wide range of materials, coatings, treatments, and design considerations to enhance safety and prevent accidents. Choosing the right solution depends on the specific requirements of the stairway, including its location, usage, and environmental conditions. By implementing these solutions, property owners can ensure safer stairways and reduce the risk of slips and falls.

Have a project and in need of guidance?

Let our experts assist you in making the right decision!