Stairpans: You Might Not Think You Know What One Is – But Chances Are You’ve Walked on One

Stairpans are everywhere. You may even have walked on one of ours. Our stairpans can be found in buildings all over the US and even a few in Canada. From some of the tallest buildings in the states, to ones with just two floors, our custom formed steel stairs can be found all over the place.

The next time you find yourself in a commercial stairwell, perhaps in an apartment building or parking garage, look down – you are standing on a stairpan!

Stairpans are support components used in the building of structural steel stairways. Metal stairpans are primarily found in commercial construction projects such as:

- Schools

- Office buildings

- Hotels

- Sports Arenas

- Malls

- Hospitals

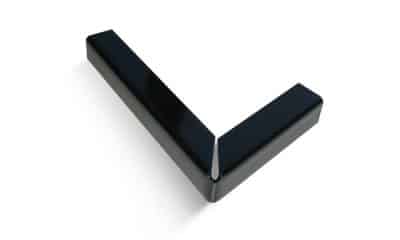

Designed to be welded between two structural stringers, or “C” channels, stairpans provide long term strength and durability wherever a high volume of foot traffic is expected.

After the pans are welded into the steel “C” channels, the stairways are rigged into position. Once in position, and attached to surrounding structural steel, concrete is poured into the tread portion of the pan to create a smooth anti-slip walking surface. The stair is ready for pedestrian traffic as soon as the concrete dries.

We Specialize in Four Main Styles of pan, which we call ‘Types’ (1, 2 , 3 and 4).

Within each ‘Type’, several customized options are available. You can get a standard pan (A), or one with a sanitary cove (B), a nosing (C), or a sanitary cove and nosing (D).

For example: a ‘Type 1A‘ stairpan would be a standard Type 1 pan. A ‘Type 1B‘ stairpan would be a Type 1 stairpan with a sanitary cove, and so on. Each Type of pan has 4 options and there are four types of pans, so there are 16 total styles offered. Click here to view the profile of each type of stairpan offered.

Furthermore, each run of stairs must have a starter riser, and a landing riser, in addition to the combination tread and riser pans which make up the bulk of the stairs, in a run of stairs. As you might have guessed, the starter riser is the first stairpan, at the base of a run of stairs, and the landing pan is the last pan, at the top of a run of stairs, where the stair meets up with the stair landing. Click here to view an example of the three stairpan profiles for our TYPE-1A Stairpan. The combination tread and riser is at the top of the diagram, the Landing Riser is in the middle, and the Starter Riser is at the bottom.

In addition to solid metal pans, we also offer perforated ones. You can learn more about them in our blog: Perforated Stairpans for Safety and Visual Appeal.

Carbon steel, stainless steel, galvanized steel and aluminum are the most common material use to fabricate the pans, and they are often primed and painted prior to pouring concrete. (Several of the pictures shown feature red primer painted stairpans, prior to concrete pour).

On the underside of the stair, carrier angles, can be welded into place, on the stringers, to help position the stairpans and to add structural integrity to the stair.

When there are multiple flights of stairs, stair landing pans are often used. Landing pans offer an advantage over other methods, since they are modular. Their smaller design and lighter weight means they can be moved into position by a few workers – instead of requiring machine lifts or hoists. Landing pans also make for a much easier and more uniform concrete pour.

For more information on stairpans and stair systems, Stair Components & Systems is your go-to resource.