Even the Romans knew how to build a spiral staircase! Spiral staircases have been desired and praised since the days of the Roman Empire. However, they offer many more benefits than just their unique appearance. Spiral staircases are often considered for several reasons including: their space efficiency, aesthetic appeal, versatility in materials and styles, cost-effectiveness, ease of installation, safety features, compliance with certain building regulations, and practicality for accessing tight or specific areas like lofts and attics. These staircases can serve as both functional and stylish elements in a variety of settings.

Why Choose A Spiral Staircase?

Spiral staircases are highly desirable for a wide variety of reasons. Spiral staircases take up less floor space compared to traditional staircases, making them ideal for small or tight spaces. They can be a practical choice for accessing lofts, attics, and mezzanine levels where space is limited and a full staircase would be cumbersome.

Spiral staircases can come in a variety of materials (wood, metal, glass, etc.) and styles (modern, classic, industrial), allowing them to fit into virtually any architectural theme. They are also aesthetically appealing, and can add a unique and elegant design element to a home or building.

Spiral staircases are also known for their ease of installation and cost-effectiveness. They are often easier and quicker to install, especially in retrofit situations or where space constraints make conventional staircases impractical. In certain environments, such as outdoor spaces, spiral staircases are notably safer as they often have a central support column which provides stability.

Designing Spiral Staircases For Commercial Use

Designing spiral staircases for commercial use involves several important considerations to ensure they meet both aesthetic and functional requirements while adhering to safety regulations and standards. Some of the initial aspects that require careful consideration before designing begins include accessibility, traffic flow, structural integrity, safety features, and compliance with building codes.

While spiral staircases can be space-efficient, they might not always be accessible for everyone, including individuals with disabilities. Analyzing the expected traffic flow is also essential in ensuring the staircase can accommodate peak usage times without causing bottlenecks or safety hazards. Engineering the staircase to support the expected load is crucial. This includes considering the central column, treads, and connections, ensuring they are capable of handling the traffic typical of commercial environments.

Incorporating safety features such as non-slip treads, adequate lighting, and handrails is another important consideration. In commercial settings, it may be necessary to design the staircase with wider treads and a gentler rise to accommodate a diverse range of users, including those with mobility issues. When designing your spiral staircase, ensure the design complies with local building codes and regulations, which often dictate specific dimensions such as tread depth, riser height, and diameter, as well as the inclusion of handrails and guardrails for safety.

How To Build A Spiral Staircase

Building a spiral staircase involves several key steps, from planning and design to construction and finishing. Here’s a step-by-step guide on how to build a spiral staircase:

The first phase of building a spiral staircase is planning and design!

- Determine Location and Size: Measure the available space and decide the staircase’s height, diameter, and location. Consider the ceiling height and the opening size.

- Comply with Building Codes: Check local building codes for regulations on tread dimensions, riser heights, handrails, and other safety requirements.

- Choose Materials: Decide on materials for the steps, central column, handrails, and balusters. Common materials include wood, metal, and glass.

- Create a Blueprint: Draw detailed plans or use design software to create blueprints, specifying all measurements and components.

- Prepare the Site: Clear the installation area and ensure it’s clean and level. Verify the dimensions and mark the center point for the central column.

The second phase includes construction and installation.

- Install the Base Plate & Erect the Central Column : Secure the base plate at the marked center point. This plate will hold the central column in place. Attach the central column to the base plate and ensure it’s plumb (perfectly vertical). Secure it at the top with a temporary brace if necessary.

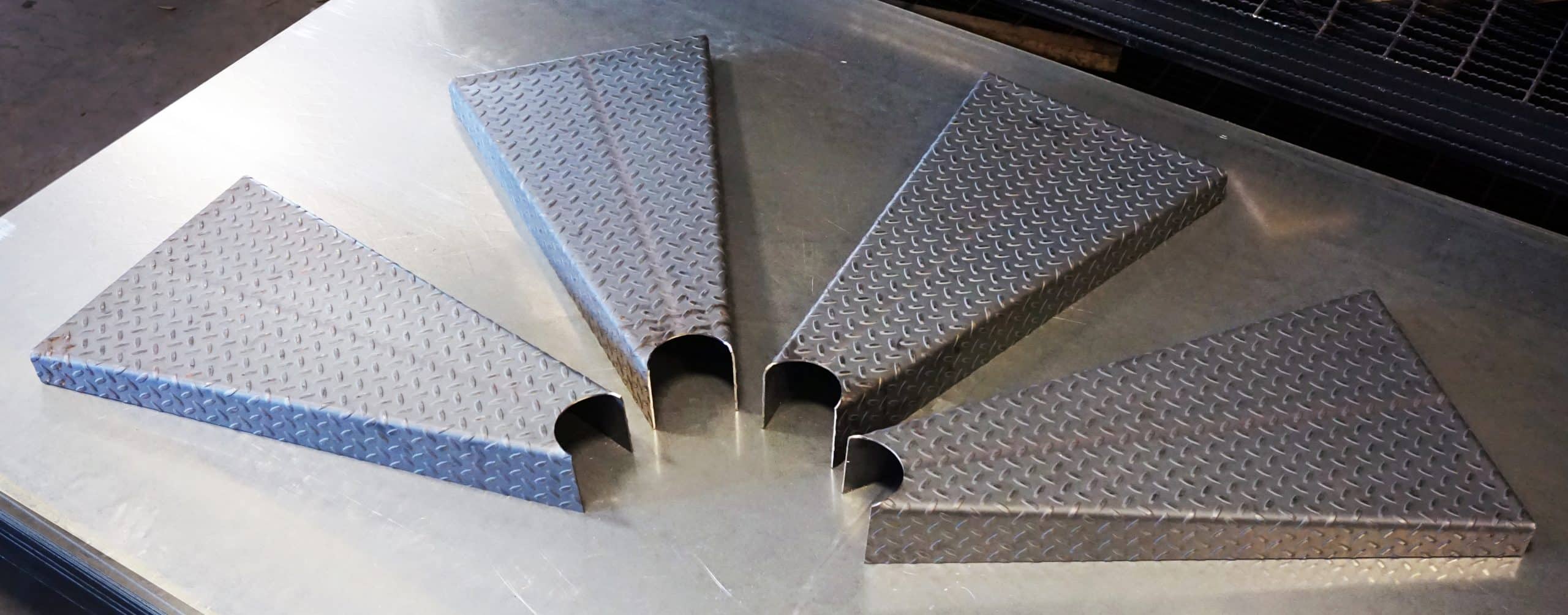

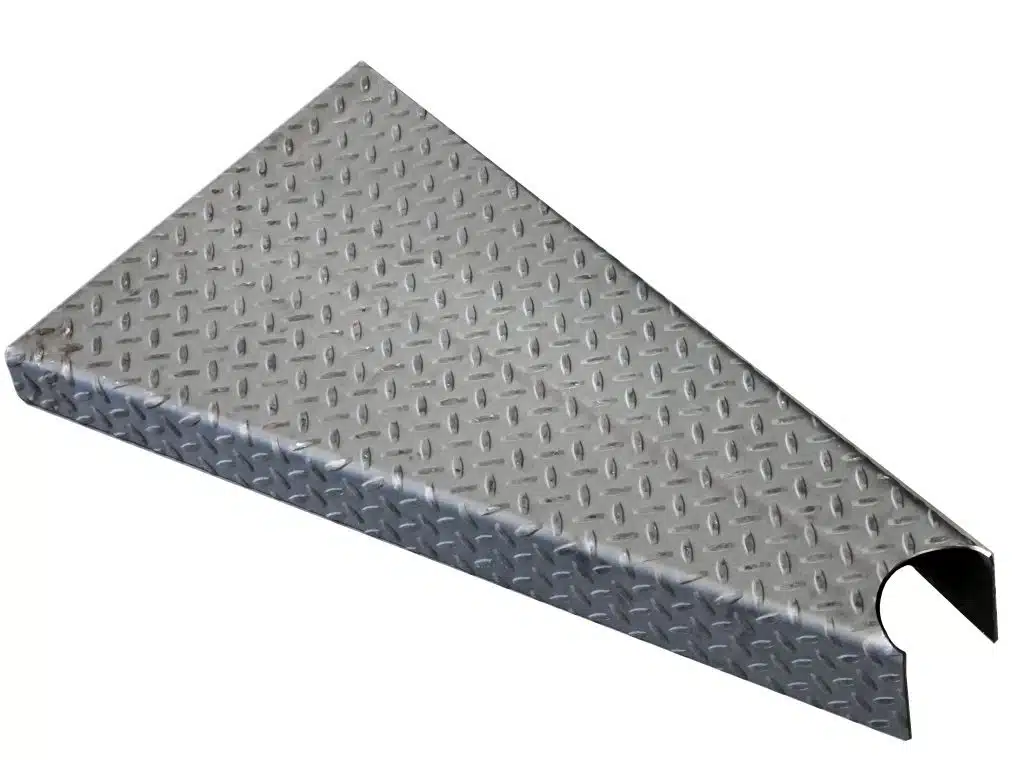

- Measure and Cut Treads: Cut treads to the desired size and shape. Ensure they are uniform. If you are using prefabricated stair treads you can eliminate this step – your treads are already manufactured to your specifications and ready to be installed!

- Attach Tread Supports & Treads: Securely attach the treads to the central column at calculated intervals, corresponding to the riser height. This process may include installing support brackets for the treads or welding them in place. Starting from the bottom, attach each tread, ensuring it’s level. Progressively work your way up the column until you finish installing the last spiral stair tread.

- Install Balusters & Handrail: Attach balusters to the outer edge of each tread. Ensure they are evenly spaced and securely fastened. Start from the bottom and work your way up, attaching the handrail to the balusters.

The final phase of how to build a spiral staircase includes finishing touches and inspection.

- Secure All Connections: Double-check all bolts, screws, and connections to ensure everything is tightly secured.

- Sand and Finish: Sand any rough edges and apply finishes (paint, stain, or sealant) to the treads, handrail, and balusters as needed. If you have installed prefabricated spiral treads, there may be little to no finishing involved, depending on the finish you have chosen.

- Safety Inspection: Conduct a thorough inspection to ensure the staircase is stable and safe. Check for any wobbly steps, loose balusters, or other issues.

Customization Options For Commercial Spiral Staircases

Customizing a commercial spiral staircase allows it to fit the specific needs and aesthetic preferences of the space. Some customization options to consider include: Choosing materials & finishes, tread design, handrails & balusters, the central column, safety enhancements, and additional features like landings.

The most commonly used materials include steel, wood, glass, concrete, or a combination of 2 or more. Popular finishes include paint, stains, powder coating, and polishing. Tread design includes deciding on shape, thickness, and surface texture. Some important safety additions to consider are non-slip treads and wider treads with a gentler rise.

Stair Components & Systems offers a wide variety of stair tread customization options available in a number of different materials and finishes. If you can envision it, we can manufacture it. Visit our website for more information on customized spiral stair treads.

Cost Considerations When Building A Spiral Staircase

When choosing your spiral staircase, it is important to take cost into consideration. This is primarily comprised of material costs, design & customization costs, labor & installation costs, safety enhancement costs, and routine maintenance costs. By carefully considering these factors, you can better estimate the cost of building a spiral staircase and ensure it aligns with your budget and design expectations.

When it comes to building materials, wood and steel remain the cheapest options, while concrete and glass are at the other end of the spectrum. Design costs depend on complexity of the staircase design, as well as additional costs like staircase finishes. Dimensions and number of treads are also two factors to consider, as they not only come with a price, but they also influence cost of labor and installation. Lastly, additional safety enhancements may be costly, but not as costly as responding to an accident! Non-slip treads and improved lighting and handrails should be seriously considered.

While there are many options for material selection, steel provides the best of both worlds, with unrivaled strength and minimized cost due to a streamlined manufacturing process. Stair Components & Systems offers a wide variety of prefabricated stairs perfect for your next project. We also offer metal fabrication services for projects requiring further customization services. For more information on manufacturing and customization capabilities, visit metalfabricationsvcs.com

Have a project and in need of guidance?

Let our experts assist you in making the right decision!